La Modelleria was founded in 1968 and since 1978 it has been producing metal models (cast iron, aluminum and bronze) for large production scale foundries.

Moreover, it also produces resin and wood equipments.

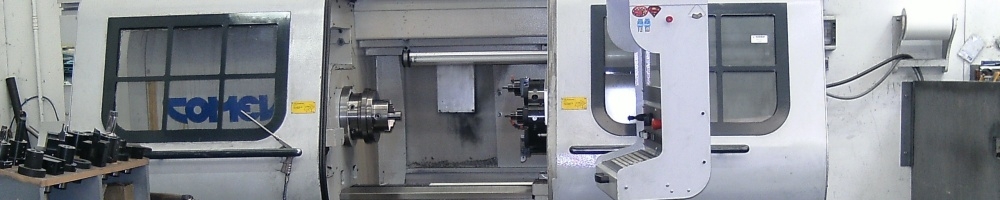

Since 1983 we have been working with high speed numerical control (CNC) machines.

The fast evolution of the mode of production, the wide spread of international competitiveness, not to mention the increasing demand for high quality products lead us to strengthen our participation on the international market through the adoption of up-to-date technologies.

La Modelleria has a 1600 mqarea as well as it owns good machines such as high speed numerical control (CNC) machines, as well as milling and drilling machines and CNC lathes.

Furthermore, we dispose of 6 CAD CAM stations. At the request of the customer we can provide 3d scanning of the tooling.

La Modelleria counts on twenty two employees: three administration and sales services managers, six qualified CAD CAM operators and twenty workers dealing with the organization and production phases.

In particular, our company deals with the oil-hydraulic and automotive sector as well as breaking systems, gearing and suspensions, turbochargers, earthmoving equipment and electrical appliances.

Nowadays more and more attention to the quality production and safety standards is required in order to be more competitive, for this reason La Modelleria chose to set some guidelines in the production and selling polices:

- The materials we buy must be in compliance with the standard requirements for the final product safety (actually, a list of approved suppliers has been created);

- During the whole production process, our goods are subjected to several controls and tests we can give evidence of. Obviously, our measuring machines are periodically tested, too;

- Extremely close controls on the final product are always carried out before the delivery and, if required, the whole documentation will be provided;

- You can count on a “non conformity management policy”, i.e. in case of a cast sampling defect (either dimensional or mould) attributable to the equipment, our company takes care of intervening without charging further expenses;

- We can efficiently manage and satisfy possible complaints;

- The delivery times are precisely respected and granted.

The quality system certification on the application of the UNI EN ISO 9001:2015 regulations gives evidence to what previously stated.